MS 25 10 | Hydraulic Guillotine Shear

Preci-Shear’s MS 25 10 guillotine shearing machine is the ultimate in heavy-weight shearing machinery. Equipped to handle large pieces, this shearing machine will cut through the toughest of materials with precision every time. Our frames are the heaviest on the market, ensuring accurate results every time. If you’re looking for a metal shear with a longer table and serious cutting capacity, look no further.

Standard Features:

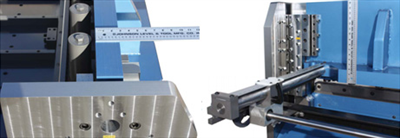

- 144” long and 48” wide with a cutting length of 121.375”

- 36" back-gauge, with precision lead screws driven by a timing belt. Fully enclosed control panel c/w low voltage controls

- All hydraulic and mechanical parts are standardized and easy to find throughout North America

- For easy handling of materials our nine support arms are rounded, also preventing damage while loading

- Two overload protection systems work by limiting hydraulic pressure & electrical amp draw

- Safety feature: If the remote foot-pedal control is released anywhere in the stroke the ram returns to "up" position

- Front operated state-of-the-art PLC touch screen control with simple go-to

- Low speed electric motor & low hydraulic working pressure ensures long life

- Blades consist of D2 high carbon premium quality tool steel

- Low rake angle to minimize work piece distortion

- 48" squaring arm c/w measurement indicator

Specifications:

| Cutting Capacity (Rated 80,000 PSI Tensile) | 1/4" MS - 3/16" SS |

| Cutting Length | 121.375" |

| Rake Angle | 0.250 per ft. |

| Strokes Per Minute | 8 full strokes |

| Number of Hold-down Cylinders | 19 |

| Motor | 15 HP 1760 RPM |

| Voltages Available | 230 / 460 / 575 3 PH.60 HZ. |

| Table Depth to Blade | 31.125" |

| Table Working Height | 35.500" |

| Footprint | 144" long x 48" wide |

| Weight (approx.) | 14,400 lbs. |

| Hydraulic Fluid | 160 liters / 42 US Gal. AW 68 or equivalent. |

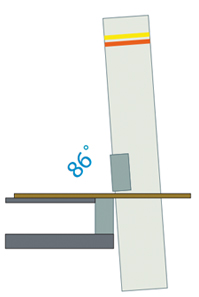

Steel cut at 86°

Using other models the ram & blade come down at a fixed relief angle which results in an offset cut, equal to the relief angle.

Using other models the ram & blade come down at a fixed relief angle which results in an offset cut, equal to the relief angle.

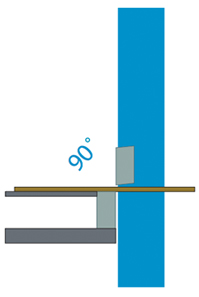

Steel cut at 90°

Precishear The ram & blade comes down at 90° to give you a straight 90° cut. Our top blade has a 5 back-bebel to ensure a clean cut.

Precishear The ram & blade comes down at 90° to give you a straight 90° cut. Our top blade has a 5 back-bebel to ensure a clean cut.

- Large bore cylinders run at low operating pressure, assuring long life on all hydraulic components

- The ram & two cylinders are connected together using two hardened micro-finished link pins

- Equal pressure & equal rake-angle are maintained throughout the full stroke of the ram

- Trouble-free hold-downs will never leak oil and will probably never require service

- The two pivot points use maintenance-free bearings that require no lubrication

- Two hold-downs on left side are installed closer together to cut small plates

- Hold-downs have large pressure pads to protect sensitive work pieces

- Allows ram to follow through below bottom blade

- All gibs have full length blood lines for grease

- Backside gibs eliminate lateral movement

- Gives ram precision cutting abilities

- 4 large gibs located front & back

- We mill the inside and outside of the frame, then the contour of the frame is milled

- All major components of our shearing machines are precision milled

- Frame strength exceeds tensile strengths of materials being cut

- Our side frames are milled from 2.250" steel plate

- Our side frames are milled on all six sides

- Low noise due to heavy-duty design

- Ram brace is bolted to the back of the ram which adds additional support

- Brace and gussets are all welded to the ram for a truly solid design

- Reinforced ram delivers ultimate rigidity and dampening

- Ram & brace are milled down to 2.75" thick

- Design eliminates deflection

- All 6 sides machined

- Easily cut differing dimensions of material without adjusting shears

- Massive frames eliminate errors and the need for adjustments

- Based on proven traditional shearing machine designs

- Completely fixed blade gap & rake angle settings

- Heavy-duty design eliminates problems

- Easily cut 1/4 inch and under materials

- No need for rake angle adjustments

- No need for blade gap adjustments

- Top and bottom blades are sectional (30.5") which allows for easy repairs

- Sectional blades are easily repaired at any local shop

- Our standard blades are D2 High Carbon Tool Steel

- Quality tested to prove high performance

- Less expensive to repair or replace

- Hold downs never leak oil, have pressure pads and generally require no servicing

- Ram & cylinders are connected with 2 hardened micro-finished link pins

- Pivot points use maintenance free bearings (no lubrication required)

- Equal pressure & rake angle is maintained throughout stroke

- See through safety guards allow for accurate cutting