MS 25 5 | Hydraulic Guillotine Shear

Preci-Shear’s MS 25 5 guillotine shearing machine is perfect for custom metal fabrication applications. It comes with the capacity to cut the most demanding materials accurately and efficiently. Its heavy duty frame offers a no-give attitude when cutting; which is why you can achieve such precise results without having to make adjustments. Get it right the first time!

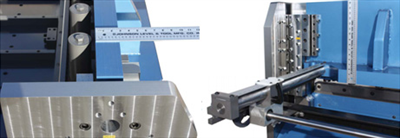

Standard Features:

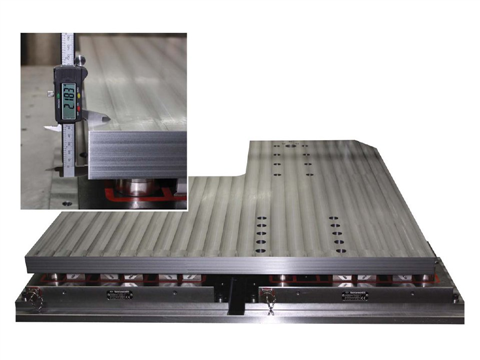

- 83” long and 42” wide with a cutting length of 60.375”

- 26" back-gauge, featuring precision lead screws driven by a timing belt

- Our four support arms are rounded for damage prevention and easy handling of materials

- All of our shearing machine’s hydraulic and mechanical parts are standardized and readily available throughout North America

- Rigged with two overload protection systems that regulate by limiting hydraulic pressure & electrical amp draw

- Ram immediately returns to the “UP” position if the remote foot-pedal control is released anywhere in the stroke

- Preci-Shear’s low speed electric motor & low hydraulic pressure ensures long life and operator safety

- Sectional blades are more efficient and easier and cheaper to repair

- Standard D2 High Carbon premium quality tool steel blades

- Front operated PLC touch screen control with simple go-to

- See-through guards allow for accurate and safe operation

- Fully enclosed control panel c/w low voltage controls

- Low rake angle to minimize work piece distortion

- 48" squaring arm c/w measurement indicator

Specifications:

| Cutting Capacity (Rated 80,000 PSI Tensile) | 1/4" MS - 3/16" SS |

| Cutting Length | 60.375 |

| Rake Angle | 0.250 per ft. |

| Strokes Per Minute | 16 full strokes |

| Number of Hold-down cylinders | 10 |

| Motor | 15 HP 1760 RPM |

| Voltages Available | 230 / 460 / 575 3 PH.60 HZ. |

| Table Depth to Blade | 31.125" |

| Table Working Height | 35.500" |

| Footprint | 83" long x 42" wide |

| Weight (approx.) | 7000 lbs. |

| Hydraulic Fluid | 160 liters / 42 US Gal. AW 68 or equivalent. |

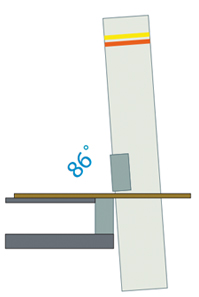

Example of steel cut at 86°:

Using other models the ram & blade come down at a fixed relief angle, which gives you an offset cut equal to the relief angle.

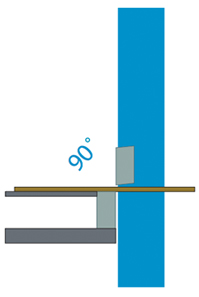

Example of steel cut at 90°:

With Preci-Shear's Guillotine Shears the ram & blade come down at 90° to give you a straight 90° cut.

Our top blade has a 5 back-bevel to ensure a clean cut.

With Preci-Shear's Guillotine Shears the ram & blade come down at 90° to give you a straight 90° cut.

Our top blade has a 5 back-bevel to ensure a clean cut.

- Large bore cylinders run at low operating pressure, assuring long life on all hydraulic components

- The ram & two cylinders are connected together using two hardened micro-finished link pins

- Equal pressure & equal rake-angle are maintained throughout the full stroke of the ram

- Trouble-free hold-downs will never leak oil and will probably never require service

- The two pivot points use maintenance-free bearings that require no lubrication

- Two hold-downs on left side are installed closer together to cut small plates

- Hold-downs have large pressure pads to protect sensitive work pieces

- Allows ram to follow through below bottom blade

- All gibs have full length blood lines for grease

- Backside gibs eliminate lateral movement

- Gives ram precision cutting abilities

- 4 large gibs located front & back

- We mill the inside and outside of the frame, then the contour of the frame is milled

- All major components of our shearing machines are precision milled

- Frame strength exceeds tensile strengths of materials being cut

- Our side frames are milled from 2.250" steel plate

- Our side frames are milled on all six sides

- Low noise due to heavy-duty design

- Ram brace is bolted to the back of the ram which adds additional support

- Brace and gussets are all welded to the ram for a truly solid design

- Reinforced ram delivers ultimate rigidity and dampening

- Ram & brace are milled down to 2.75" thick

- Design eliminates deflection

- All 6 sides machined

- Easily cut differing dimensions of material without adjusting shears

- Massive frames eliminate errors and the need for adjustments

- Based on proven traditional shearing machine designs

- Completely fixed blade gap & rake angle settings

- Heavy-duty design eliminates problems

- Easily cut 1/4 inch and under materials

- No need for rake angle adjustments

- No need for blade gap adjustments

- Top and bottom blades are sectional (30.5") which allows for easy repairs

- Sectional blades are easily repaired at any local shop

- Our standard blades are D2 High Carbon Tool Steel

- Quality tested to prove high performance

- Less expensive to repair or replace

- Hold downs never leak oil, have pressure pads and generally require no servicing

- Ram & cylinders are connected with 2 hardened micro-finished link pins

- Pivot points use maintenance free bearings (no lubrication required)

- Equal pressure & rake angle is maintained throughout stroke

- See through safety guards allow for accurate cutting